Injection Moulding

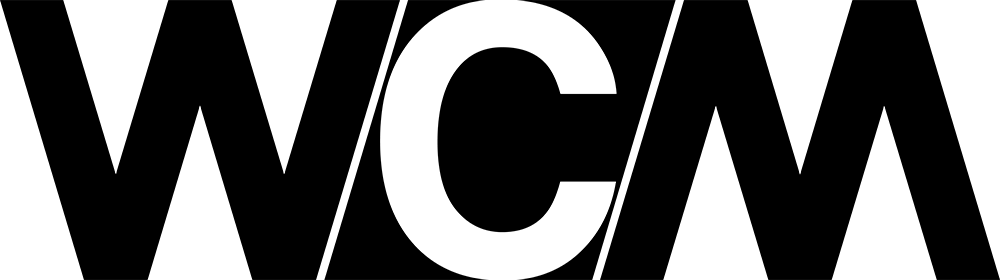

WCM's plastic Injection Moulding capabilities and processes compliment one another to serve the automotive industry for Prototype, series and Low Volume Production

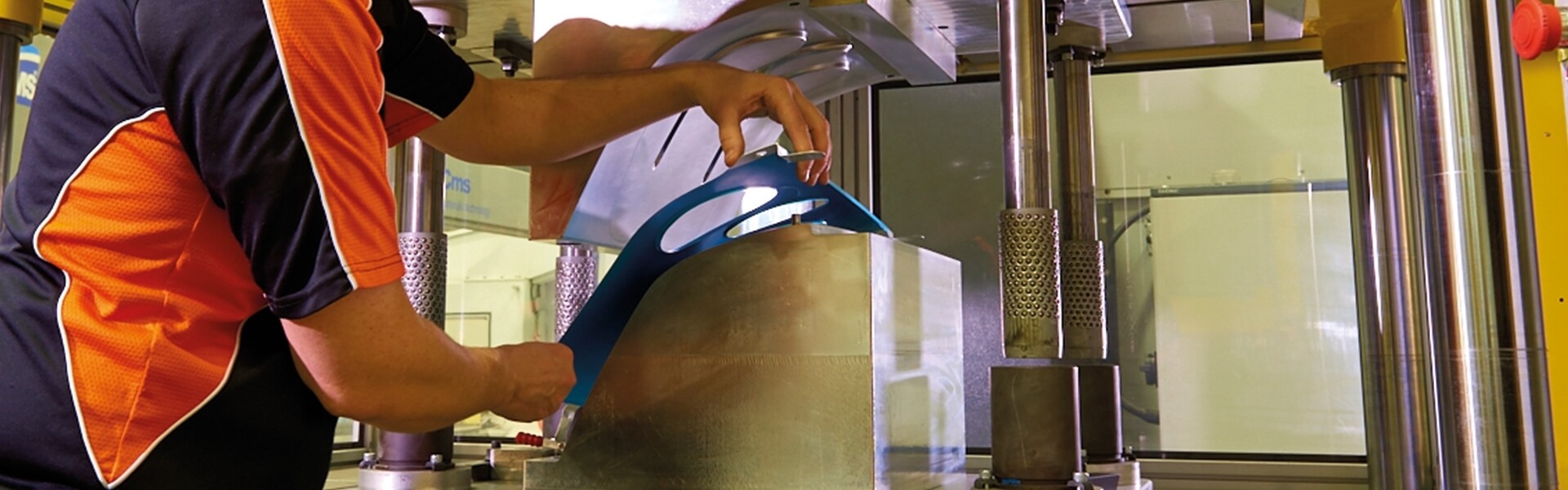

WCM supplies plastic parts to many of the World’s leading automotive brands, using its expertise in injection moulding to serve customers. Moulded parts are supplied in batches ranging from 5 and over 10,000 parts per order, with large warehouse facilities to supply off-the-shelf parts controlled through the latest MRP software system and barcoding. As production innovators, WCM continue to invest in the latest all-electric Injection Moulding equipment, offering greater efficiency and improved environmental awareness compared to hydraulic moulding machines.

Plastic Part Examples

There are a number of Injection Moulding options available through the range of production machinery available, ranging from 120-1,500 tonne. The Production team support all enquiries to ensure parts are manufactured using the most efficient injection moulding route. There are a wide range of Plastics available to support production needs and the Production team are on hand to advise during the selection process.

Common Materials

- Acrylonitrile Butadiene / Styrene - ABS

- Acetal - POM

- Nylon (Polyamide) - PA6/PA66 Glass Fill

- Polyethylene - PE

- Polypropylene - PP

- Polyvinyl Chloride - PVC

- Low Density Polyethylene - LDPE / LLDPE

- High Density Polyethylene - HDPE

- Polyphenylene Oxide - PPO

- Polypropylene - HPPP and CPPP

- Acrylate Styrene Acrylonitrile - ASA

- Acrylic - PMMA

- Acetate - (CAB)

- Polycarbonate - PC

- Polyesters - PET / PBT

- Styrene Acrylonitrile - SAN

- Polysulphone - PES / PSU / PEEK

- Polyphenylene Sulphide - PPS

- Polyurethane - PUR

- Polystyrene - PS / General Purpose - GPPS / High Impact - HIPS

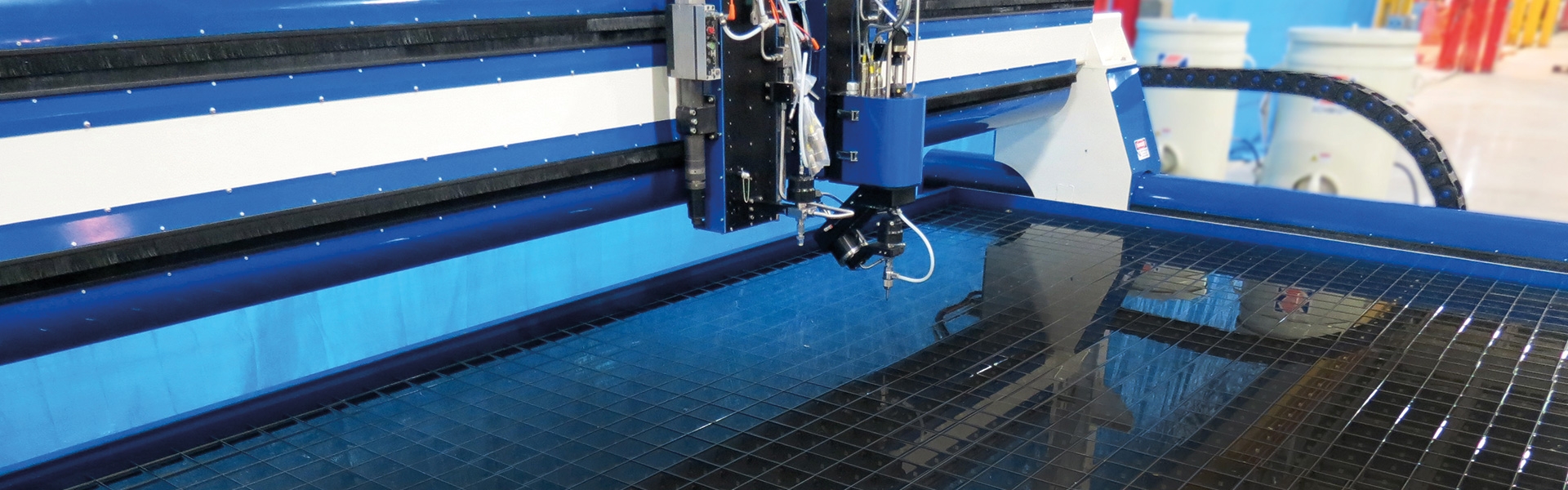

Tooling is produced at WCM Tooling facilities located in the UK and China, where expert tool makers oversee the production process. Having both operational sites provides customers with access to competitive tooling solutions. All tools are validated by quality processes in the UK using standard European plastics.

The Production Team in Injection Moulding work closely with Design and Engineering to make sure your part is fully developed for production