waterjet

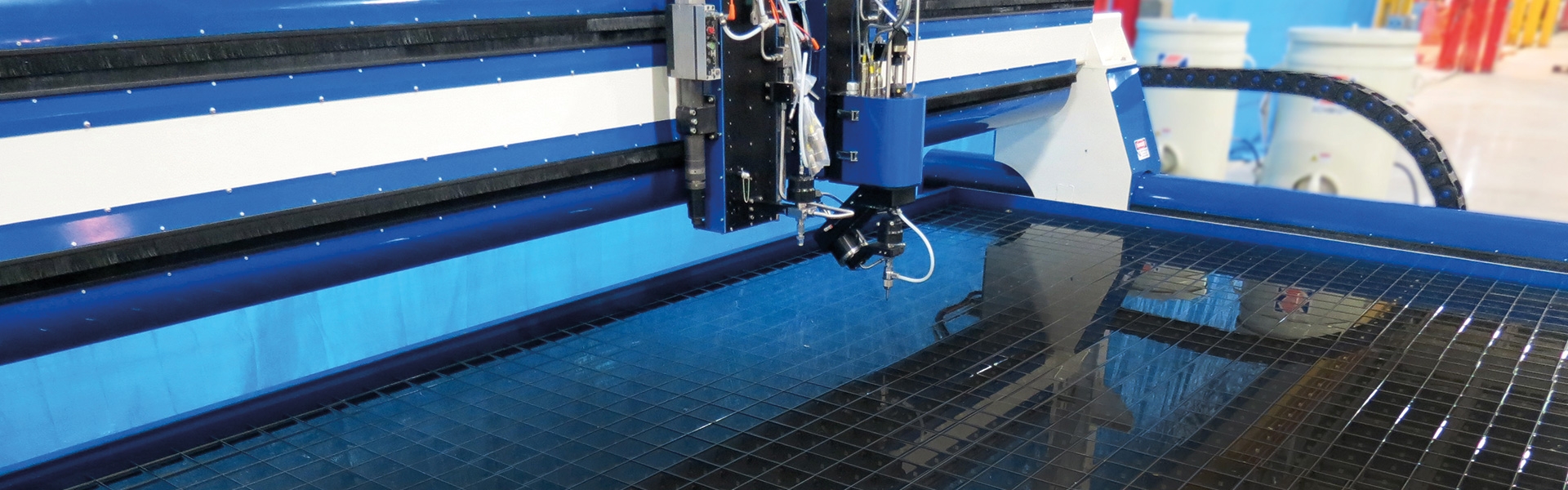

WCMs waterjet cutting capabilities utilise the latest ultra-high pressure machines to create precise cut parts from raw materials including Metals, Plastics, Glass and Stone

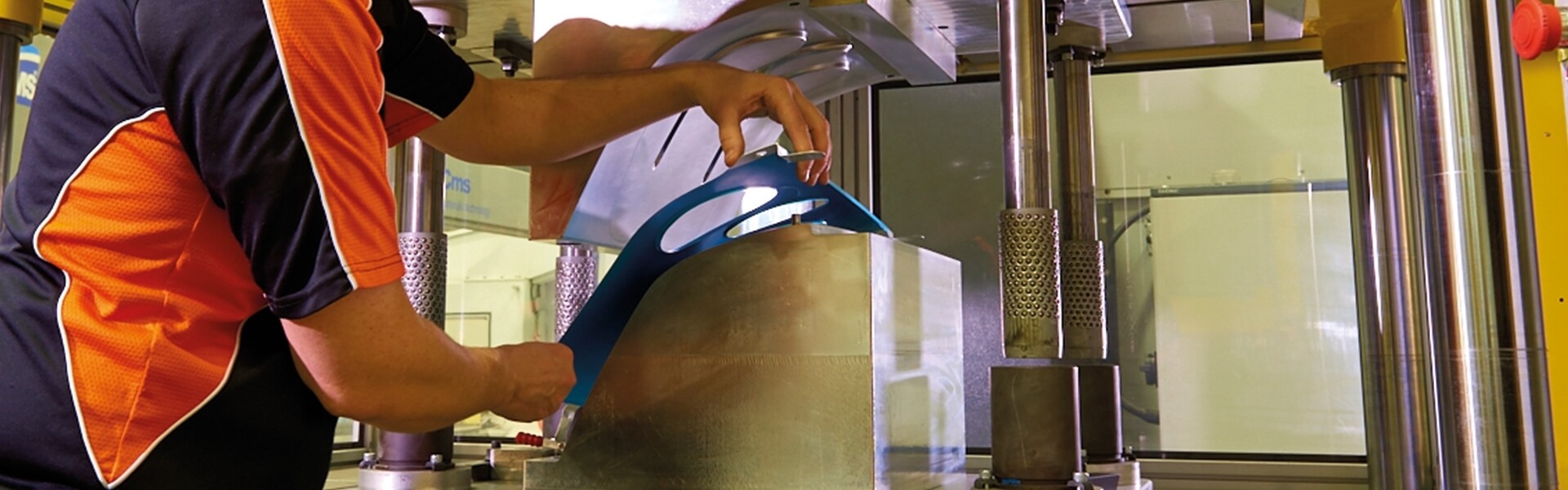

The waterjet cutting process at WCM uses advanced techniques to control the speed and kerf of the jet through 5 axis cutting head technology. This allows cuts to be inclined through the rotation of the head throughout the cutting process. All movements are monitored fully to automatically regulate the distance of the cutting head from the material being processed. With a tolerance of +/- 0.1mm, WCM produce intricate designs with a high level of accuracy.

When compared to other cutting methods such as laser, plasma and routing, waterjet cutting provides a much higher level quality finish. A smoother, clean cut is left, free of burnt edges, chips, burrs and slag, saving unnecessary time and money for secondary processing.

Waterjet Cutting Facilities at WCM serve many of the Production Processes with Quality, Precision Cut Parts