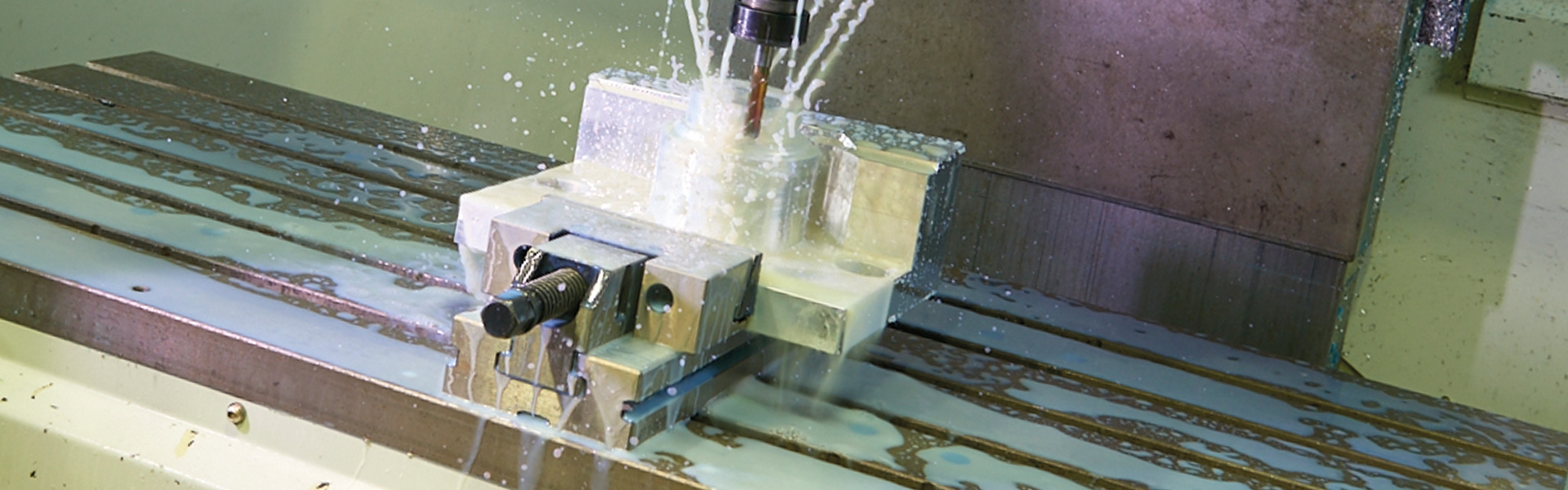

Production tools

WCM Tooling Division tool systems are designed, developed and manufactured within the Group’s 2 tooling manufacturing centres located in the UK and China

WCM production tools run fully auto and can incorporate the latest hot runner systems and various mechanical or electro-mechanical ejection. Production tools can be surface etched or textured. All tools are checked and verified, and sample moulded parts are run before any batch moulding commences.

Tools are built for generic use or for use on specific moulding machines. WCM continues to research, develop and introduce new methods of tooling so that production materials can be used in low and medium volume production applications.

3S Tooling Technology for Soft Feel Instrument Panels

The 3S service has 3 stages. Firstly a master of the Skin is created using Rapid Manufacturing methods and from these a Nickel shell tool is made and then slush moulded using production material. At the second stage the IP main Structure is produced from a CNC Aluminium Injection Mould Tool. The third and final stage is where the "Soft Feel" is created through a foam tool, whereby the Skin on the A surface and the main IP Structure on the B surface are held in place, allowing foam to be injected into the tool to adhere parts together.

The Tooling Division at WCM have the resources and technical experience needed to progress your tooling needs for manufacture